The packing materials used in the equipment of petrochemical enterprises need to meet requirements such as corrosion resistance, high mass transfer efficiency, large processing capacity, and low pressure drop. At the same time, they must be able to adapt to harsh working conditions such as high temperature, high pressure, or strong corrosion. The following is an analysis of the commonly used packing types and application scenarios in the petrochemical industry:

I. Commonly Used Packing Types in the Petrochemical Industry

(1) random Packing

Characteristics: Simple structure, easy installation, suitable for situations with moderate requirements for mass transfer efficiency or complex working conditions.

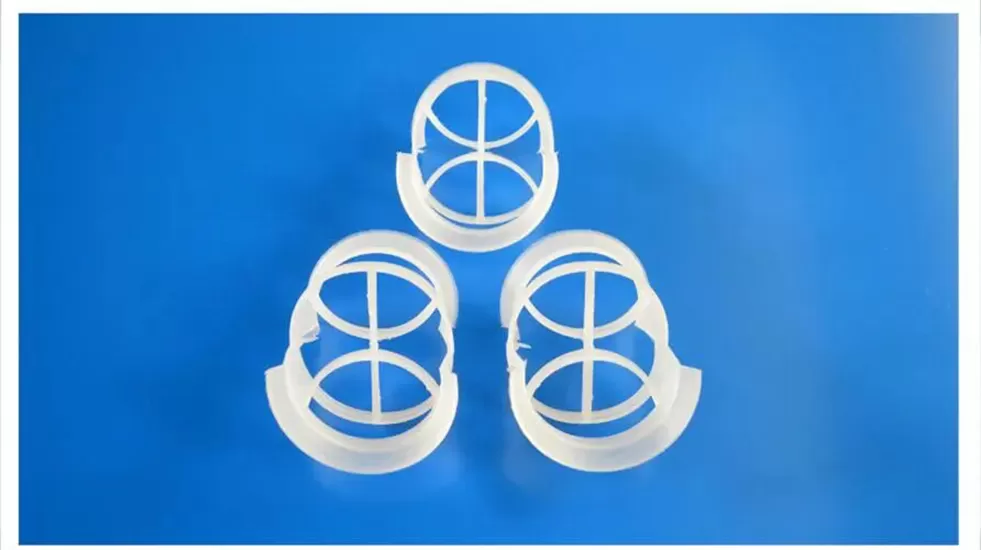

Pall Ring

Structure: Rectangular window holes are opened on the side walls of the Raschig ring, and tongue-shaped bends are added inside the ring to point towards the center.

Advantages: Large specific surface area (about 180-350 m²/m³), low gas flow resistance, uniform liquid distribution, large operational flexibility.

Application: Widely used in distillation, absorption, and desorption processes, such as atmospheric and vacuum distillation towers, gas absorption towers (desulfurization, decarbonization).

Intalox Saddle

Structure: Asymmetric arc-shaped structures on both sides, similar to a saddle, with toothed grooves on the surface.

Advantages: More uniform liquid distribution, no nesting during stacking, large specific surface area (about 160-360 m²/m³), low resistance.

Application: Commonly used for acid gas absorption (such as H₂S removal), methanol distillation towers, styrene separation towers.

Metal Hy-Pak Rectangular Saddle

(2) Regular Packing

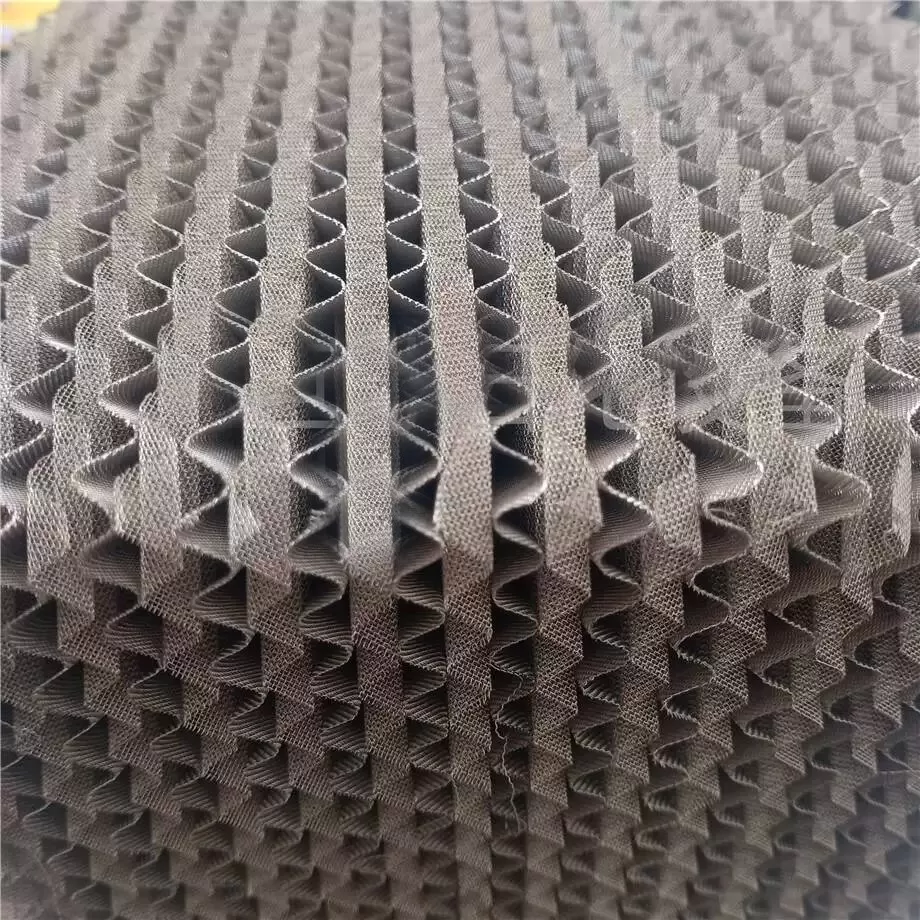

Metal Wire Mesh Packing

Structure: Metal wire mesh is pressed into a corrugated shape and stacked into a disc.

Advantages: Large specific surface area (up to 1000 m²/m³), extremely high mass transfer efficiency (8-20 theoretical plates per meter), low liquid holding capacity, low resistance.

Plastic Structured Packing

Material: Polypropylene (PP), polyvinyl chloride (PVC), etc., corrosion-resistant plastics.

Advantages: Lightweight, resistant to acid and alkali corrosion, specific surface area 250-500 m²/m³, suitable for low-temperature and non-high-temperature conditions.

Application: Acidic water desulfurization towers, steam stripping towers in wastewater treatment, dilute acid absorption towers.