Ethylbenzene absorption and separation towers typically select appropriate packing materials based on separation process requirements, material characteristics (such as the boiling point difference between ethylbenzene and other components, corrosiveness, viscosity, etc.) and operating conditions (such as temperature, pressure, and processing capacity). Common types of packing materials include the following:

1. Structured packing

Structured packing features regular structure and neat arrangement, with high mass transfer efficiency, making it suitable for scenarios with high separation accuracy requirements.

Metal plate corrugated packing

Characteristics: Made by stamping thin metal sheets into corrugated shapes, with small holes on the corrugated plates to increase the mass transfer area, uniform fluid distribution, low resistance, and high flow rate.

Applicable scenarios: In ethylbenzene separation, if the material viscosity is low, there is no strong corrosiveness, and high mass transfer efficiency is required (such as the separation of ethylbenzene from benzene and toluene), this type of packing is often chosen.

Advantages: High separation efficiency, can reduce tower height, and save floor space.

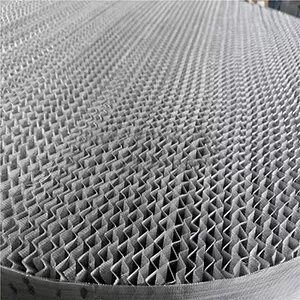

Metal wire mesh corrugated packing

Characteristics: Made of metal wire mesh in a corrugated structure, with a large specific surface area, extremely high mass transfer efficiency, small liquid holdup, and low resistance.

Applicable scenarios: Suitable for scenarios in ethylbenzene separation with extremely high purity requirements (such as fine chemical product purification), or when the processing capacity is small but high separation accuracy is required.

Notes: Higher cost. If the material contains particles or is prone to fouling, it may cause blockage and should be used with caution.

2. Random packing

Random packing is easy to install, has strong adaptability, and is suitable for scenarios with large processing capacity or complex material characteristics.

Metal step ring packing

Characteristics: Short cylindrical shape with one end expanded into a bell shape, providing more uniform fluid distribution, low resistance, high flow rate, and better mass transfer efficiency than traditional packing such as Raschig rings.

Applicable scenarios: In ethylbenzene separation, if the material flow rate is large, the operating flexibility is high (such as when the load fluctuates), or it contains a small amount of impurities that are not prone to clogging the packing, step rings can be selected.

Plastic polypropylene (PP) Pall ring packing

Characteristics: Made of plastic, it is corrosion-resistant, lightweight, and low-cost, with windows on the ring walls for good fluid flow.

Applicable scenarios: If the ethylbenzene material contains corrosive components (such as acidic gases) or the operating temperature is low (polypropylene can withstand temperatures below about 100°C), plastic Pall rings can be used to reduce equipment corrosion risks.

Ceramic Raschig ring / step ring packing

Characteristics: Made of ceramic, it has strong corrosion resistance and high temperature resistance, but has a lower void fraction and higher resistance.

Applicable scenarios: Only used in special conditions where the ethylbenzene material has strong corrosiveness (such as containing inorganic acids) and high temperature, and should be carefully selected based on mass transfer efficiency requirements.