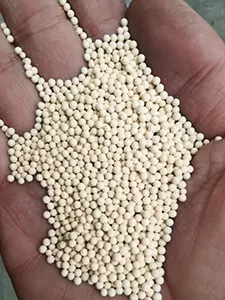

3A molecular sieve is a type of aluminosilicate adsorbent with a uniform pore size of 3 angstroms. It is mainly composed of silicon, aluminum, and oxygen atoms, with potassium cations in its structure, which gives it strong hydrophilicity. This sieve is highly selective, allowing only small polar molecules like water (2.8 angstroms) to enter its pores while excluding larger molecules such as ethanol (4.4 angstroms). It is widely used in drying gases, solvents, and in glass laminates due to its precise moisture removal ability.

4A molecular sieve, on the other hand, has a pore size of 4 angstroms. Its composition is similar to 3A, but with sodium cations instead of potassium. This larger pore size enables it to adsorb a wider range of molecules, including water, methanol (3.8 angstroms), and carbon dioxide (3.3 angstroms). It finds applications in detergent production as a builder and in natural gas dehydration, where the removal of multiple small impurities is required.

When it comes to water absorption speed, 3A molecular sieve is faster than 4A molecular sieve. The 3-angstrom pores of 3A sieve are precisely matched to the size of water molecules, creating a tighter fit that enhances the adsorption process. Additionally, 3A sieve has a stronger polar attraction to water molecules, which accelerates moisture uptake. In industrial settings, when used as packing in drying equipment, 3A molecular sieve can quickly reduce the moisture content in the target medium, making it more efficient in scenarios where rapid drying is needed.