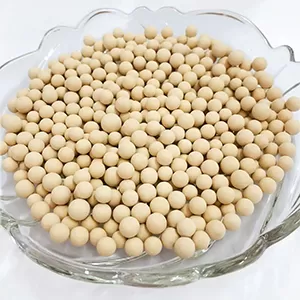

5A molecular sieve and 3A molecular sieve are distinct in pore size and adsorption capabilities, shaping their industrial roles. 3A sieve features 3-angstrom pores, selectively adsorbing small polar molecules such as water (2.8Å) while blocking larger substances like ethanol (4.4Å). This makes it ideal for precise drying applications, including solvent purification and glass laminate moisture control, where targeted moisture removal is critical.

5A molecular sieve, with 5-angstrom pores, accommodates larger molecules, adsorbing compounds like methane (3.8Å), carbon dioxide (3.3Å), and n-paraffins (up to 4.9Å). Its broader selectivity suits separation processes, such as isolating linear hydrocarbons from branched ones in petrochemical refining or purifying hydrogen streams by removing impurities like propane.

In industrial packing, 3A sieve’s smaller pores reduce pressure drop in high-flow systems, while 5A’s larger pores offer higher capacity for compatible molecules. 3A’s strict size exclusion minimizes product loss in drying, whereas 5A’s versatility enables multi-component separation. Both retain the molecular sieve’s regenerability, but 5A requires higher regeneration temperatures (up to 350°C) compared to 3A’s 200–300°C range. These differences in pore size, selectivity, and operational needs define their unique applications across industries.