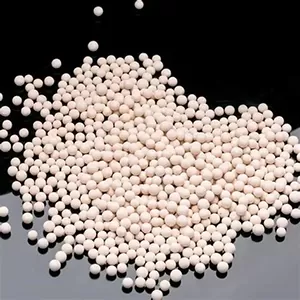

3A molecular sieve excels in selective adsorption, with 3-angstrom pores that strictly target small polar molecules like water, avoiding co-adsorption of larger compounds such as ethanol. This precision minimizes product loss in purification, a key advantage for applications like solvent drying. Its strong hydrophilicity ensures rapid moisture uptake, enhancing efficiency in time-sensitive processes. However, its narrow pore size limits versatility—it cannot adsorb molecules larger than 3Å, restricting use in multi-impurity removal scenarios.

4A molecular sieve, with 4-angstrom pores, offers broader adsorption capacity, capturing water, methanol, and carbon dioxide. This versatility makes it cost-effective for processes requiring multi-component purification, such as natural gas treatment. Its larger pores also allow higher overall adsorption volumes compared to 3A. Yet, this breadth is a drawback: it may adsorb desirable small molecules, reducing product yield. Additionally, 4A’s selectivity is lower, making it unsuitable for applications needing strict exclusion of specific compounds.

In packing, 3A’s smaller pores reduce pressure drop in high-flow systems but require more frequent regeneration due to limited capacity. 4A’s larger pores handle higher loads but may cause increased pressure drop in dense packing. Both retain the molecular sieve’s regenerability, though 3A’s stricter selectivity and 4A’s versatility define their suitability for distinct industrial needs.