Metal Taylor Ring is an efficient tower packing developed based on the plastic Taylor Ring. It inherits the structural advantages of the Taylor Ring and, relying on the characteristics of metal materials, exhibits excellent performance in harsher industrial environments. Its structure is also composed of 12 small rings arranged radially to form a large oblate sphere, similar to a spherical shape formed by a spiral spring connected end-to-end, which makes it perform well in gas-liquid mass transfer processes.

Product Features

- High Strength and High Temperature Resistance : Metal materials endow the Taylor Ring with extremely high mechanical strength, which can withstand large pressure and temperature changes. It is suitable for harsh working conditions such as high temperature and high pressure, and is applicable to the demanding production environments of chemical, petroleum, metallurgical and other industries.

- Excellent Thermal Conductivity : Compared with plastic materials, metal Taylor Ring has better thermal conductivity. In processes involving heat transfer, it can promote rapid heat transfer and uniform distribution, improving process efficiency.

- High Mass Transfer Efficiency and Stability : Inheriting the advantages of the Taylor Ring structure, the metal ring has a reasonable porosity, ensuring sufficient gas-liquid contact and a long liquid residence time, resulting in high and stable mass transfer efficiency. At the same time, the characteristics of the metal surface help reduce liquid film resistance, further optimizing the mass transfer effect.

- Corrosion Resistance Options : Different metal materials can be selected according to the characteristics of the medium. For example, stainless steel (304, 316, etc.) has good corrosion resistance and can cope with corrosive media such as acids and alkalis; carbon steel is suitable for non - corrosive or low - corrosive environments, taking into account economy and practicability.

Application Fields

- High - Temperature and High - Pressure Reaction Towers : Metal Taylor Ring can play a stable role in high - temperature and high - pressure reaction towers, and is suitable for chemical reaction processes such as ammonia synthesis and methanol synthesis, ensuring the efficient progress of the reaction.

Oil and Gas Separation and Refining : In petroleum refining, oil and gas separation and other processes, it can be used in distillation towers, absorption towers and other equipment to achieve precise separation and refining of oil and gas components and improve product purity.

Metallurgical and Coking Industries : In the gas purification of the metallurgical industry and the gas treatment of the coking industry, it can be used to remove impurity gases, purify process media, and ensure the smooth progress of subsequent production.

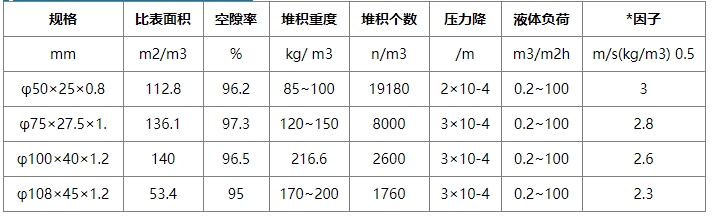

Product Parameter Table

Specification (D×H×δmm) | Number of Stacks (n/m³) | Specific Surface Area (αm²/m³) | Void Fraction (ε%) | Stacked Weight (kg/m³) | Common Materials |

25×9×0.8 | 180000 | 200 | 85 | 280 | 304 Stainless Steel, 316 Stainless Steel, Carbon Steel |

40×15×1.0 | 50000 | 190 | 88 | 320 | |

50×18×1.2 | 28000 | 185 | 90 | 300 | |

76×25×1.5 | 9500 | 130 | 92 | 260 | |

100×30×1.8 | 4200 | 105 | 93 | 240 | |

150×45×2.0 | 1200 | 75 | 95 | 210 |

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)