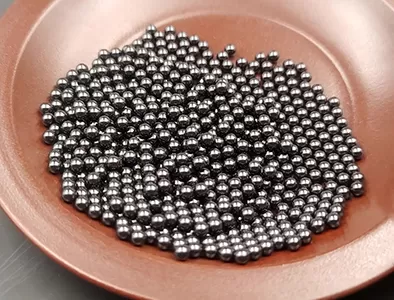

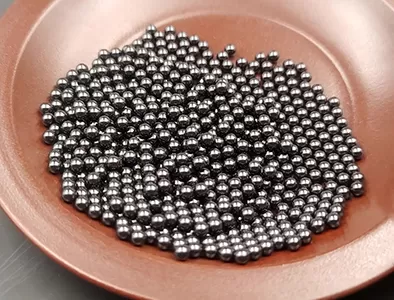

Silicon nitride ceramic balls are advanced engineering ceramics made from silicon nitride (Si₃N₄), featuring high strength, excellent thermal shock resistance, and low density. These properties make them suitable for demanding applications across various industries. Their unique atomic structure gives them a combination of toughness and hardness that outperforms many other ceramic materials, allowing them to withstand extreme conditions.

One of the most notable characteristics of silicon nitride ceramic balls is their ability to maintain structural integrity under rapid temperature changes. Unlike some ceramics that crack when exposed to sudden heat or cold, these balls resist thermal shock, making them ideal for high - temperature environments such as gas turbines and industrial furnaces. They also have a low coefficient of friction, which reduces wear and energy loss in moving parts.

In the aerospace industry, silicon nitride ceramic balls are widely used in aircraft engines and auxiliary systems. Their lightweight nature helps reduce overall weight, improving fuel efficiency, while their high strength ensures reliability under the extreme pressures and temperatures of flight. They are also used in precision bearings for aerospace equipment, where their durability and low friction contribute to smooth operation.

The automotive sector benefits from these ceramic balls in high - performance engines and transmission systems. They can withstand the high temperatures and stresses of engine operation, reducing friction and extending the lifespan of components. In racing vehicles, where performance and reliability are critical, silicon nitride ceramic balls are often chosen for their ability to handle extreme conditions.

In the field of industrial machinery, silicon nitride ceramic balls serve as effective components in pumps, valves, and compressors. Their resistance to corrosion and wear makes them suitable for handling aggressive fluids and abrasive materials, ensuring long - term performance with minimal maintenance. They are also used as packing in high - temperature reaction vessels, where their thermal stability and chemical inertness prevent contamination of processes.

The electronics industry utilizes silicon nitride ceramic balls in high - precision equipment. Their electrical insulation properties and dimensional stability make them ideal for use in sensors, semiconductors, and other electronic components that require accurate positioning and resistance to heat.

Additionally, in the medical field, these ceramic balls are used in specialized devices such as dental drills and surgical instruments. Their biocompatibility, along with their strength and resistance to sterilization processes, makes them safe and reliable for medical applications.

Overall, silicon nitride ceramic balls are versatile materials that play a crucial role in advancing technology across multiple industries, offering a unique set of properties that enable innovation and improved performance in demanding applications.