The production of plastic packing involves a series of processes from raw material selection to finished product inspection, ensuring quality and performance. This article will explore how plastic packing is produced.

Raw material selection is the first critical step. The choice of plastic material depends on the intended application of the packing. Common materials include polypropylene (PP), polyethylene (PE), polyvinyl chloride (PVC), and polytetrafluoroethylene (PTFE). PP is widely used due to its good chemical resistance, moderate heat resistance, and cost-effectiveness, making it suitable for general industrial applications. PE is chosen for its flexibility and impact resistance, often used in low-temperature environments. PVC offers excellent corrosion resistance to certain chemicals but has lower heat tolerance. PTFE, though expensive, is selected for extreme conditions involving high temperatures and highly corrosive substances. Raw materials are typically sourced in the form of pellets or resin, which may be mixed with additives like UV stabilizers, antioxidants, or colorants to enhance specific properties.

The next stage is material preparation and compounding. The plastic pellets are mixed with any necessary additives in a mixer to ensure uniform distribution. This mixture is then fed into a hopper, where it is dried to remove moisture—moisture can cause defects like bubbles or voids in the final product during processing. Drying is especially important for materials like PP and PVC, which are hygroscopic to some extent. The dried mixture is then ready for the molding process.

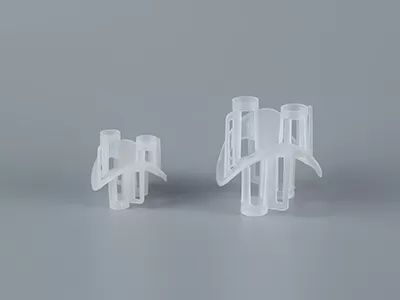

Molding is the core process that gives plastic packing its specific shape. Injection molding is commonly used for producing structured or complex-shaped packing, such as pall rings or specialized saddles. In this process, the molten plastic is injected under high pressure into a mold cavity that has the exact shape of the desired packing. Once the plastic cools and solidifies, the mold opens, and the finished part is ejected. For simpler shapes like raschig rings or balls, extrusion molding may be employed. Here, the plastic is melted and forced through a die with the desired cross-sectional shape. The extruded material is then cut to the required length as it cools. Blow molding is another method, though less common, used for creating hollow structures. For large quantities of small, irregularly shaped packing like random saddle rings, rotational molding might be utilized, where the plastic is melted inside a rotating mold, coating the inner surface to form the shape.

After molding, the plastic packing undergoes trimming and finishing. Excess material, such as flash from injection molding or rough edges from extrusion, is removed using cutting tools or automated trimming machines. This step ensures that the packing has smooth surfaces and precise dimensions, which are crucial for proper functioning—rough edges can disrupt fluid flow or cause uneven distribution. Some packing may also undergo surface treatment, such as coating with anti-stick or anti-corrosion layers, depending on their application requirements.

Quality inspection is a vital part of the production process. Each batch of plastic packing is inspected for dimensional accuracy using calipers or gauges to ensure they meet design specifications. Visual inspections check for defects like cracks, warping, or uneven surfaces. Mechanical tests may be performed on sample pieces to verify strength, impact resistance, or chemical resistance, depending on the material and intended use. For example, samples may be submerged in corrosive chemicals to test their durability, or subjected to pressure tests to assess their structural integrity. Packing that fails to meet quality standards is rejected or recycled.

Finally, the 合格 (qualified) plastic packing is cleaned, sorted, and packaged. Cleaning removes any residual debris or dust from the manufacturing process. Packing is sorted by size and type to ensure uniformity, then packaged in bags, boxes, or pallets for storage and transportation. Packaging must protect the packing from damage during transit and include labels with information such as material type, dimensions, batch number, and manufacturer details.

In summary, the production of plastic packing involves raw material selection, compounding, molding, trimming, quality inspection, and packaging. Each step is carefully controlled to ensure the final product meets the required performance, durability, and dimensional standards for its intended industrial applications.