Plastic packing is categorized into several types based on structure and design, each serving distinct industrial purposes. This article will outline the main types of plastic packing.

random packing is a widely used type, characterized by its irregular shape and random arrangement in columns or towers. pall rings are a typical example, featuring a cylindrical structure with openings on the sidewalls and inward-projecting tabs. These design elements reduce pressure drop while maintaining a large specific surface area, making them efficient for gas-liquid contact in absorption and distillation processes. saddle rings, another form of random packing, combine the curved shape of saddles with the rigidity of rings, promoting uniform fluid distribution and minimizing channeling—ideal for applications requiring high mass transfer efficiency, such as wastewater treatment.

structured packing is defined by its ordered, uniform structure, usually composed of corrugated plastic sheets stacked in a specific pattern. The corrugations are inclined at angles (typically 30 or 45 degrees) to create a zigzag path for fluids, enhancing mixing and contact. This type offers high specific surface area and low pressure drop, making it suitable for high-efficiency separation processes like fractional distillation in the pharmaceutical and fine chemical industries. Grid packing, a subset of structured packing, consists of crisscrossed plastic rods or strips forming a grid-like structure. It provides large void spaces, allowing high flow rates and resisting fouling, which is beneficial for handling viscous fluids or those containing solids, such as in food processing.

Ring-type packing encompasses various cylindrical designs beyond Pall rings, including

raschig rings—the earliest form of ring packing. Raschig rings are simple hollow cylinders with equal height and diameter, offering cost-effectiveness and mechanical strength. They are used in general-purpose applications where moderate efficiency is sufficient, such as bulk chemical storage. Berl saddles, though less common today, are curved, saddle-shaped packing that provides good liquid distribution and is used in low-pressure drop scenarios.

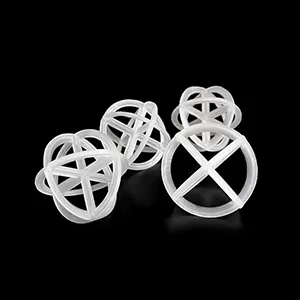

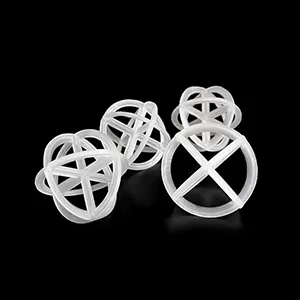

Ball packing, as the name suggests, is spherical in shape. Made from plastic materials like PP or PE, it has a smooth surface and simple structure. While its specific surface area is lower than other types, it is lightweight and resistant to corrosion, making it suitable for small-scale equipment or laboratory applications where low pressure drop is prioritized.

In addition to these main categories, there are specialized plastic packing types designed for specific needs. For example, theta rings feature internal partitions to enhance turbulence, improving mass transfer in demanding processes. Intalox saddles, an evolution of Berl saddles, have a more symmetric shape to optimize fluid flow and contact. These specialized types cater to niche industrial requirements, balancing efficiency, pressure drop, and durability.

In summary, plastic packing types include random packing (Pall rings, saddle rings), structured packing (corrugated sheets, grid packing), ring-type packing (Raschig rings, Berl saddles), ball packing, and specialized designs. Each type’s structure and properties determine its suitability for different industrial processes, from general separation to high-efficiency applications.