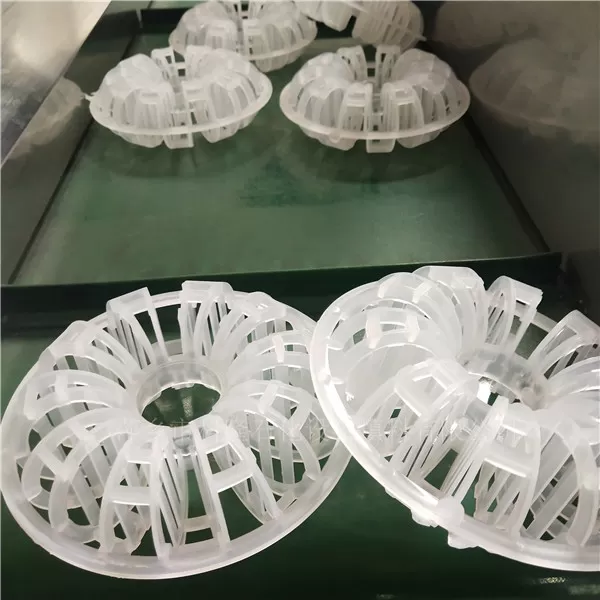

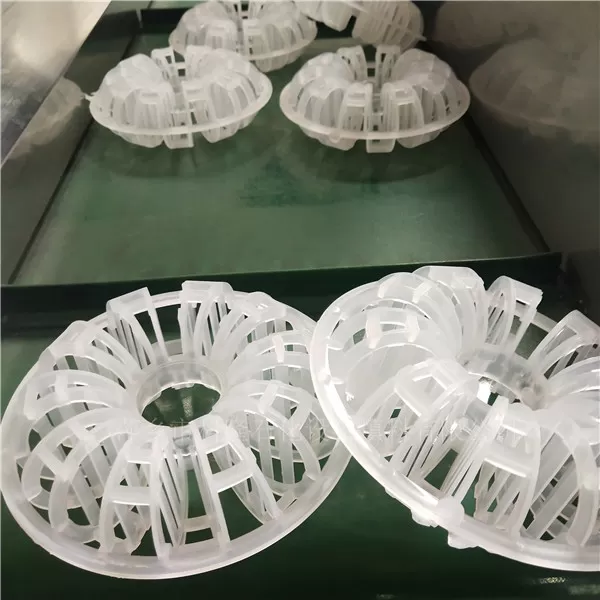

Proper stacking of

plastic packing is essential to ensure its quality and prevent damage during storage and transportation. This article will discuss the specific requirements for stacking plastic packing.

The choice of stacking site is crucial. The site should be flat, dry, and well - ventilated to avoid moisture accumulation, which can cause mold growth or degradation of the plastic material. It should also be away from direct sunlight, as prolonged exposure to ultraviolet (UV) rays can lead to brittleness and discoloration of the packing. Additionally, the site must be free from sharp objects or debris that could scratch or puncture the plastic packing. If stored outdoors, a waterproof and UV - resistant cover is necessary to provide extra protection.

Stacking height is another important requirement. The height should be controlled to prevent the packing at the bottom from being crushed due to excessive weight. Generally, the maximum stacking height for plastic packing ranges from 1.5 to 2 meters, depending on the type and strength of the packing. For example, lighter and more fragile plastic packing, such as those with complex structures, should be stacked at a lower height compared to more rigid ones. Overstacking can not only damage the packing but also create safety hazards, as unstable stacks may collapse.

The way of stacking must be orderly and stable. Plastic packing should be stacked in a neat manner, with each layer aligned properly to ensure even weight distribution. Using pallets can help improve stability and facilitate handling with forklifts. It is advisable to avoid pyramid - shaped stacking, as this can lead to uneven pressure and increase the risk of collapse. For cylindrical or irregularly shaped packing, separators or dividers can be used between layers to prevent shifting and maintain stability.

Protection against mechanical damage is necessary during stacking. The packing should be handled with care to avoid dropping or hitting, which can cause cracks or breaks. When using machinery like forklifts, operators must be cautious to not collide with the stacks. Additionally, stacking different types or sizes of plastic packing together should be avoided unless they are compatible, as this can lead to uneven pressure and damage. Each type of packing should have its own designated stacking area.

Labeling and identification are also part of the stacking requirements. Clear labels should be placed on the stacks indicating the type, quantity, and date of storage of the plastic packing. This helps in easy inventory management and ensures that older stock is used first, reducing the risk of long - term storage degradation. Labels should be waterproof and visible from a distance to facilitate quick identification.

Regular inspection of the stacked plastic packing is important. The stacks should be checked periodically for signs of damage, such as deformation, cracks, or moisture. If any issues are found, the affected packing should be moved and inspected further. Additionally, the stability of the stacks should be monitored to prevent collapse, especially after any disturbance or movement in the storage area.

In summary, the requirements for stacking plastic packing include selecting an appropriate site, controlling stacking height, ensuring orderly and stable stacking, protecting against mechanical damage, proper labeling, and regular inspection. Adhering to these requirements helps maintain the quality of the plastic packing, ensures safety, and facilitates efficient storage and handling.