Plastic garland packing has unique characteristics that make it widely used in various industrial processes. This article will explore the main characteristics of plastic garland packing.

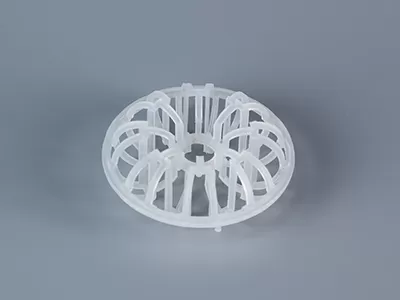

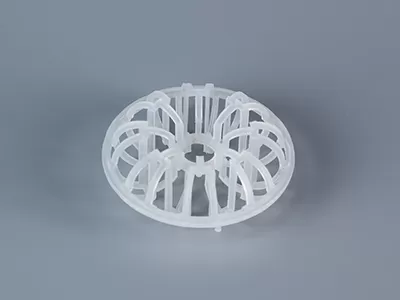

The structural design is one of its notable features. Plastic garland packing typically has a ring - like structure with multiple lobes or projections extending outward, resembling a garland. This design increases the specific surface area, allowing for better contact between fluids and the packing. The gaps between the lobes also facilitate the uniform distribution of gases and liquids, promoting efficient mass transfer in processes such as absorption, distillation, and extraction.

Lightweight is another key characteristic. Made from plastic materials like polypropylene (PP) or polyethylene (PE), plastic garland packing is much lighter than metal or ceramic packing. This reduces the load on the equipment, making installation easier and lowering the requirements for the structural strength of the supporting devices. It also simplifies transportation and handling, which is beneficial for large - scale industrial applications.

Good chemical resistance is a significant advantage. Plastic garland packing can resist the corrosion of many acids, alkalis, and organic solvents, depending on the specific plastic material used. For example, PP garland packing performs well in most chemical environments, while polytetrafluoroethylene (PTFE) garland packing can withstand more aggressive chemicals. This makes it suitable for use in various chemical processing industries where corrosive media are present.

Cost - effectiveness is also a prominent trait. Compared to metal or ceramic packing, plastic garland packing has a lower production cost. Its long service life, combined with low maintenance requirements, further enhances its cost - performance ratio. This makes it an economical choice for many industrial applications, especially in large - scale processes where a large quantity of packing is needed.

Moderate mechanical strength is another characteristic. While not as strong as

metal packing, plastic garland packing has sufficient mechanical strength to withstand the normal operating conditions in most industrial processes. It can resist the impact of fluid flow and maintain its structural integrity during long - term use. However, it may not be suitable for extremely high - pressure or high - velocity environments where excessive force could cause damage.

Easy cleaning and maintenance are also worth mentioning. The smooth surface of plastic garland packing and its open structure make it less prone to fouling and easier to clean. Deposits or contaminants can be removed more effectively through methods like flushing, which helps maintain the packing's performance and extends its service life. This reduces downtime for maintenance and ensures continuous operation of the equipment.

In summary, plastic garland packing is characterized by its unique structural design, lightweight nature, good chemical resistance, cost - effectiveness, moderate mechanical strength, and ease of cleaning and maintenance. These characteristics make it a versatile and practical choice for a wide range of industrial processes, contributing to efficient and economical operations.