The pall ring has been significantly improved upon the Rasch ring. Although the outer diameter of the ring is also equal to its height, two rows of windows with inwardly extending tongue-like pieces are cut on the ring wall. Each layer of window holes has 5 tongue-like pieces. This structure improves the gas-liquid distribution, makes full use of the inner surface of the ring, and enhances the efficiency of gas-liquid distribution and transfer. It is generally made of metal, plastic or ceramic.

Ceramic material:

The ceramic pall ring possesses excellent resistance to acids, alkalis, heat and oxidation. It can withstand the corrosion of various inorganic acids, organic acids and organic solvents except hydrofluoric acid, and its operating temperature can reach above 900℃. Its price is relatively low, being the least expensive among the three materials. However, the ceramic pall ring also has disadvantages such as fragility, heavy weight and inconvenient installation. It is widely used in various packing towers such as drying towers and absorption towers in industries like chemical engineering, metallurgy, coking, and sulfuric acid production.

Advantages: Strong resistance to acid and alkali (except for hydrofluoric acid), can withstand a temperature of over 900℃, resistant to oxidation, and low in price.

Applications: Suitable for use in the chemical, metallurgical, coking, and sulfuric acid industries, and can be applied to fillers of packing towers in corrosive and high-temperature environments such as drying towers and absorption towers.

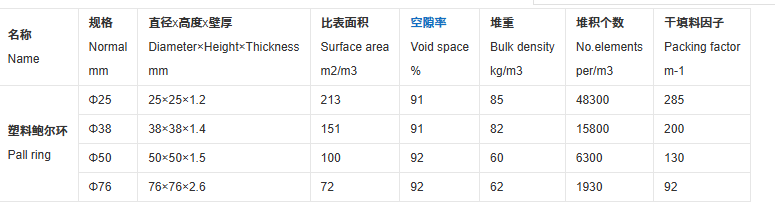

The materials of plastic ball rings include PP (polypropylene), RPP (reinforced polypropylene), PVC (polyvinyl chloride), CPVC (chlorinated polyvinyl chloride), PVDF (polyvinylidene fluoride), and PTFE (polytetrafluoroethylene). They have the characteristics of light weight, non-breakability, and resistance to chemical corrosion. Their operating temperature range in various media is 60-280℃. However, plastic ball rings are not resistant to high temperatures, strong acids, or strong alkalis, and are prone to oxidation. They are mainly used in various separation, absorption, and desorption devices in the petroleum, chemical, and chlor-alkali industries.

Advantages: Light weight, non-breakability, convenient installation, resistance to corrosion by most chemical media, and diverse material options (PP, PVC, PVDF, etc.).

Applications: Mainly for the petroleum, chemical, and chlor-alkali industries, used in separation, absorption, and desorption devices, suitable for medium-temperature and non-extreme corrosive working conditions.

Metal ball rings are usually made of materials such as carbon steel, stainless steel (such as 304, 316, 316L, etc.) and alloys. They have the advantages of thin walls, resistance to both cold and heat, large porosity, high flow rate, low pressure drop, low resistance, good separation effect, long service life, etc. The heat resistance of metal ball rings is moderate, capable of withstanding a certain degree of acids and alkalis, but not strong acids or strong alkalis, and they are relatively expensive. They are suitable for vacuum distillation towers, carbon dioxide degassing towers, etc., and are widely used in packing towers in the petrochemical, fertilizer, environmental protection and other industries.

Advantages: Thin wall, high void fraction, large flow rate, low pressure drop, excellent separation effect, resistance to thermal shock, long service life.

Applications: Suitable for the petrochemical, fertilizer, and environmental protection industries. It is commonly used in vacuum distillation towers, carbon dioxide degassing towers, etc., which require high separation efficiency and flow rate for packed towers.

PTFE pall ring

The PTFE (polytetrafluoroethylene) fluoroplastic ball ring is made from PTFE. It is a special type of material for ball rings and inherits the basic form of plastic materials while possessing the unique properties of PTFE. The operating temperature range is typically from -200℃ to 260℃.

Advantages:

It has extremely strong corrosion resistance and can withstand strong acids, strong bases, strong oxidants and various organic solvents. It hardly reacts with any substances.

It has excellent high-temperature and low-temperature resistance, and can work stably in extreme temperature differences without deformation or performance degradation.

The surface is smooth and non-adhesive, the material throughput rate is high, it is not prone to scaling or blockage, and the maintenance frequency is low.

It has excellent chemical stability, a long service life, and is non-toxic and harmless, meeting the hygiene requirements of industries such as food and medicine.

It retains the basic advantages of plastic ball rings, such as light weight, convenient installation, and not easy to break. The ball ring has been significantly improved on the raschig ring. Although the outer diameter of the ring is also equal to the height, two rows of windows with inwardly extending tongue pieces are opened on the ring wall. Each layer of window holes has 5 tongue pieces. This structure improves the gas-liquid distribution, makes full use of the inner surface of the ring, and improves the efficiency of gas-liquid distribution and transmission. It is generally made of metal, plastic or ceramic.