Ceramic balls can be classified by composition and application. By application, they can be categorized as ceramic balls for bearings, grinding, packing, heat storage, sandblasting, adsorption, etc. In fact, ceramic balls have many names. Ceramic balls are a general term for various ceramic materials such as zirconia, alumina, silicon carbide, silicon nitride, and boron carbide. Heng'erwo Chemicals can produce all kinds of ceramic balls.

Ceramic balls, also known as packing balls or ceramic spheres, are industrial materials widely used in the petroleum, chemical, fertilizer, natural gas and environmental protection industries. They are mainly used as covering and supporting materials for catalysts in reactors and as packing materials in towers, and can also be used as grinding media.

I. Ceramic balls for grinding

Alumina balls

Alumina grinding balls are high-hardness grinding media made from bauxite, roller powder, and industrial alumina powder as the main raw materials through processes such as batching, molding, and high-temperature firing. They are classified into three types based on alumina content: medium alumina balls (60%-65%), medium-high alumina balls (75%-80%), and high alumina balls (over 90%). Among them, high alumina balls can be further divided into grades such as 90 porcelain, 92 porcelain, 95 porcelain, and 99 porcelain. Due to their lower cost, medium and medium-high alumina balls are mostly used for coarse grinding of ceramic bodies. High alumina balls, with their high wear resistance and corrosion resistance, are widely applied in the fine grinding of ceramic glazes, chemical raw materials, and metal minerals.

At present, Helvo Chemical can produce high-purity alumina balls with purities of 99%, 99.9%, and 99.99% using high-purity alumina powder, which can be used for fine grinding.

2. Zirconia balls

Zirconia balls are produced in various ways and have different zirconia contents, with the highest reaching 95%, and the remaining 5% being yttria binder. Zirconia content can range from 65% to 95%, with 65%, 80%, and 95% being the most commonly used. The higher the zirconia content, the harder the balls. However, some customers ask for 100% zirconia balls, which is like making balls out of sand. Sand alone cannot be made into balls; cement is needed. In this case, the 5% yttria acts as the cement, binding the sand together. Therefore, please do not ask if we can make zirconia balls with more than 95% zirconia content. If you manage to buy zirconia balls with more than 95% zirconia content, when you get old, I'll sell you health supplements.

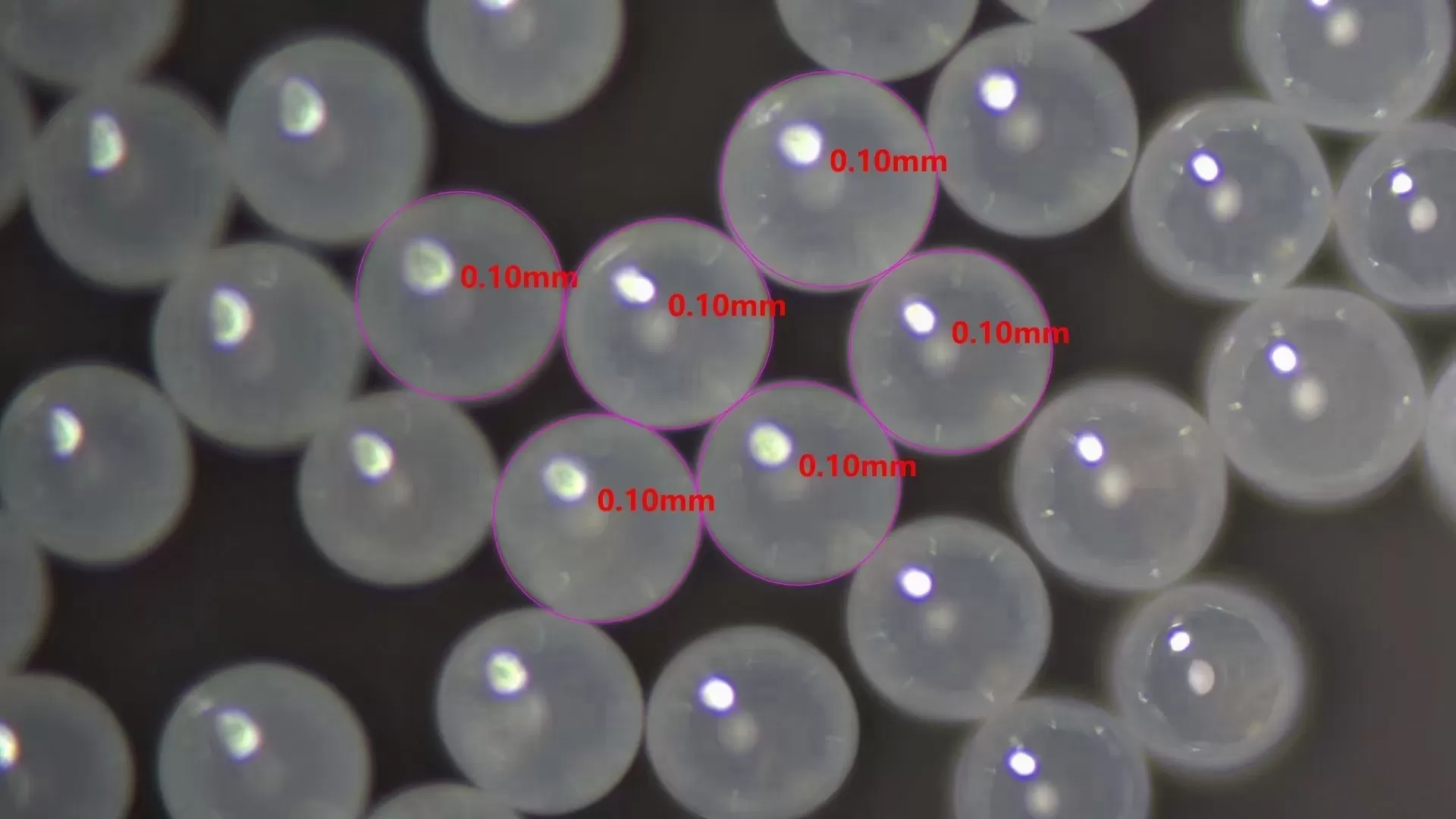

Specification: 0.03mm - 50mm. The production difficulty, production methods, costs and quotations of small balls and balls for playing are different.

Zirconia balls for bearings: Currently, the precision can reach G5 level, mainly used in environments with high precision requirements such as ball valves and bearings.

Yttria-stabilized zirconia balls: with 95% zirconia content, they are currently among the hardest and most widely used grinding beads, and are extensively utilized in various industries.

Zirconium silicate beads: With 65% zirconia content, zirconium silicate beads can be used in situations where the amount required is small and the standards are not high. All indicators are worse than those of yttria-stabilized zirconia beads.

Zirconium aluminum composite beads: With the addition of alumina components, alumina can enhance its toughness and increase the degree of wear resistance, achieving high cost-effectiveness in grinding effects in specific scenarios.

3. Silicon nitride balls

Silicon nitride balls also have the function of grinding, but the price of silicon nitride balls is much higher than that of zirconia balls and alumina balls. Therefore, unless it is absolutely necessary to use them, they are not recommended.

Silicon nitride grinding balls are a type of grinding medium made from high-performance ceramic materials. They feature high hardness, wear resistance, high-temperature resistance and chemical stability, and are widely used in fields such as ceramics, electronic materials, and food processing.

Core Features

High Hardness: Mohs hardness reaches 9.2-9.5, second only to diamond, with strong wear resistance.

High-temperature resistance: Melting point is approximately 1900°C, and it can operate stably at a high temperature of 1500°C.

Low density: The density is lower than that of metal materials, reducing equipment load and enhancing high-speed grinding efficiency.

Chemical stability: It has strong resistance to corrosive substances such as acids, alkalis and solvents, avoiding contamination of the grinding materials.

II. Ceramic Balls for Bearings

Zirconia bearing balls

Performance features:

High strength and high toughness: Zirconia ceramic balls have high strength and toughness, with a flexural strength of ≥1000Mpa and a fracture toughness of 12-14Mpa・m¹/². They can withstand significant external force impacts and are not prone to cracking.

High hardness and wear resistance: They have extremely high hardness, approaching that of diamond, and excellent wear resistance. They can endure prolonged wear and maintain good performance under heavy loads or high-speed rotation, thereby extending the service life of bearings.

Corrosion resistance: They exhibit outstanding corrosion resistance, being inert to most corrosive substances except hydrofluoric acid and hot concentrated sulfuric acid. They are not prone to rust or corrosion and are suitable for use in chemically corrosive environments.

High-temperature resistance: At 600°C, their strength and hardness remain almost unchanged, allowing them to operate stably in high-temperature environments. They are suitable for applications in furnaces, aircraft engines, and other high-temperature scenarios. Low friction coefficient and high rotational speed: Zirconia ceramic balls are lightweight, with a density of approximately 78% that of steel. This reduces the centrifugal force and friction coefficient during bearing operation, enabling higher maximum rotational speeds.

Non-magnetic and electrically insulating: They possess non-magnetic and electrically insulating properties, making them suitable for use in electronic and electrical equipment where magnetic and electrical performance requirements are specified.

Silicon nitride bearing balls

Performance features: High hardness and wear resistance: With a hardness of over HV1700, it is several times that of traditional bearing steel, capable of withstanding heavy loads and having excellent wear resistance, which can significantly extend the service life of bearings. Low density and lightweight: With a density of approximately 3.2g/cm³, it is only about 40% of that of steel. During high-speed rotation, it can reduce centrifugal force, lower friction and energy loss, and improve the operational efficiency of equipment. High-temperature resistance and stability: With a melting point of up to 1900℃, it maintains good mechanical properties in high-temperature environments and can operate stably for long periods at temperatures below 1200℃, with an instantaneous high-temperature resistance of up to 1500℃. Corrosion resistance: It has strong resistance to acids, alkalis and other chemical substances, and can be used in seawater for long periods, making it suitable for corrosive environments.

III. Ceramic Balls for Packing Materials

Filling ceramic balls are inert support / filtration materials used in tower equipment in the chemical, petroleum and other industries. Their core function is to support catalysts and distribute media, and they also have the characteristics of wear resistance and high temperature resistance. Basic overview: Filling ceramic balls are made from raw materials such as kaolin and alumina through batching, molding and high-temperature sintering. They are mostly spherical in appearance, but there are also special shapes such as cylindrical and ring-shaped. Their color varies depending on the raw materials, including white and gray, and their surface can be dense and smooth or have an open-pore structure.

Core performance features

High strength and wear resistance: After sintering, the structure is dense, with high compressive strength, not easy to break, capable of withstanding the weight of the catalyst and medium impact inside the tower, and has a long service life.

Good chemical stability: It is inert to most chemical media except strong acids and alkalis, does not react with materials, and does not contaminate products.

High-temperature resistance and thermal shock resistance: It can work for a long time in high-temperature environments above 1000℃, and is not prone to cracking when there are sudden temperature changes, making it suitable for high-temperature reaction scenarios.

Controllable pore structure: Ordinary ceramic balls have a low porosity and high density, while open-pore ceramic balls or multi-pore ceramic balls have certain pores, which can assist in the dispersion of gas and liquid and adsorb impurities.

Main Types and Uses

Common solid ceramic balls: Mainly used in the bottom and middle of tower equipment as a catalyst support layer to prevent catalyst loss and evenly distribute gas and liquid media, ensuring reaction efficiency.

Perforated ceramic balls: With evenly distributed holes on the surface, they have a larger specific surface area and are suitable for scenarios where enhanced gas-liquid contact and impurity filtration assistance are required. They can also be used as carriers for low-load catalysts.

Perforated ceramic balls

Inert alumina ceramic balls: With a higher alumina content (commonly 92%, 95%, etc.), they have better hardness and high-temperature resistance, and are used in tower equipment under high-temperature, high-pressure, and strong-corrosion conditions.

Inert ceramic balls

IV. Ceramic Balls for Adsorption

molecular sieve

Molecular sieves are also ceramic balls fired at high temperatures. They can also be made into strips and can be ground into powder.

It can be classified into categories such as 3A, 4A, 5A, 13X, and 13XRPG.

The core functions of molecular sieves are molecular-level shape-selective separation, adsorption purification, and catalytic conversion. They also have ion-exchange properties and are widely applicable to the separation and reaction requirements of multiple industries.

Core Function: Shape-Selective Separation and Purification Utilizing a uniform microporous structure, substances are screened based on molecular size, shape or polarity to achieve precise separation.

Typical applications: natural gas dehydration and desulfurization, air separation for oxygen/nitrogen production, separation of mixed hydrocarbons (olefins/alkanes), and dehydration of ethanol to produce anhydrous ethanol.

2. Activated alumina

Activated alumina is a porous and high specific surface area adsorption material of aluminum oxide (Al₂O₃), whose core functions are adsorption and drying, catalytic carrier and impurity removal. It features high adsorption capacity and stability. Basic overview: Activated alumina is made from aluminum oxide hydrate through shaping, drying and high-temperature activation. It is mostly spherical, cylindrical or granular in appearance, with a color of white or slightly yellowish. Its interior is filled with uniform micropores, and the specific surface area can reach over 200-300 m²/g, with a loose and porous structure.

Core performance features

High adsorption performance: It has a strong adsorption force on water, polar molecules and some impurities, with a large adsorption capacity, and can deeply dehydrate or remove trace impurities.

Good regenerability: After adsorption saturation, it can be desorbed and regenerated by heating (150-300℃) or purging, allowing for multiple reuse and a long service life.

Strong chemical stability: It is stable to most chemical media except strong acids and strong bases, does not react with the treated substances, and does not contaminate the products. High mechanical strength: After molding, the structure is firm, wear-resistant, and pressure-resistant, and is not prone to pulverization, making it suitable for industrial devices such as fixed beds and fluidized beds.

Good thermal stability: It can work for a long time at temperatures below 500℃ and still maintain its porous structure and adsorption performance at high temperatures. Main types and uses Adsorption type activated alumina: It mainly features dehydration and impurity removal functions, and is used for gas/liquid drying and water purification, such as dehydration of compressed air and desulfurization of natural gas.

Catalyst carrier type activated alumina: As a catalyst carrier, it is loaded with metals or metal oxides and is used in catalytic reactions in fields such as petrochemicals and environmental protection.

Fluoride-removing activated alumina: Specifically designed for fluoride removal in drinking water and industrial wastewater, it has a strong adsorption capacity for fluoride ions and meets the water quality standards.

Typical application fields

Gas drying: It is used for deep dehydration of industrial gases such as compressed air, natural gas, hydrogen, and oxygen to prevent water in the gas from affecting equipment operation or product quality.

Water treatment: In addition to removing fluoride from drinking water, it can also remove arsenic, heavy metal ions from water, and adsorb pollutants in industrial wastewater treatment.

Petrochemicals: As a catalyst carrier for reactions such as catalytic cracking and hydrofining, or for dehydration, desulfurization and dewaxing of oil products.

Environmental protection engineering: used for waste gas purification (such as adsorbing VOCs, sulfur dioxide), sewage treatment, and catalyst recovery and regeneration.

Food and pharmaceuticals: It is used for drying food-grade gases and dehydrating and purifying raw materials for medicines, meeting the purity requirements of the food and pharmaceutical industries.