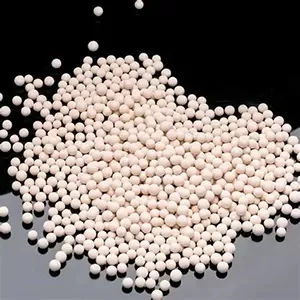

molecular sieve waste gas treatment systems operate by passing contaminated streams through a bed of specialized molecular sieve packing. The sieve’s tailored pore size (typically 3–10 angstroms) and surface chemistry enable selective adsorption of specific pollutants, such as benzene, toluene, or hydrogen sulfide, while allowing harmless gases like nitrogen to pass through.

The process begins with pre-treatment—filtering out particulates to prevent clogging the molecular sieve pores. The cleaned gas then flows into the adsorption column, where pollutants are trapped by the sieve’s polar or hydrophobic interactions, depending on the target compounds. For example, hydrophilic sieves excel at removing moisture and polar gases, while hydrophobic types target non-polar VOCs.

Once saturated, the molecular sieve undergoes regeneration, usually via heating or pressure swing, to desorb trapped pollutants for safe disposal or recycling. This allows the molecular sieve to be reused, making the solution cost-effective and sustainable.

Industrial applications include treating emissions from chemical plants, refineries, and painting facilities. The system’s efficiency depends on factors like gas flow rate, temperature, and sieve type, with proper packing design ensuring maximum contact time for optimal pollutant removal.