molecular sieve adsorption relies on a combination of pore size exclusion and molecular interactions, making it highly selective. Its crystalline structure features uniform pores, typically ranging from 3 to 10 angstroms, which act as molecular sieves—only molecules small enough to enter these pores are adsorbed.

Beyond size selection, polarity plays a key role. Water, carbon dioxide, and other polar molecules are strongly attracted to the sieve’s surface due to electrostatic forces, enhancing adsorption. This dual mechanism ensures that even among molecules of similar size, polar ones are preferentially adsorbed, a trait critical in drying and purification processes.

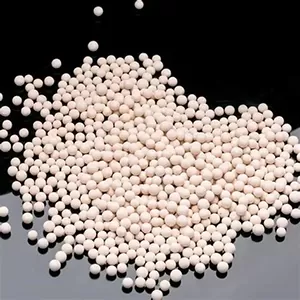

The packing of molecular sieve in industrial systems, such as adsorption columns, maximizes surface contact with the target stream. As the stream flows through the packing, molecules that fit the pore size and exhibit sufficient polarity are trapped within the sieve’s structure, while larger or non-polar molecules pass through unimpeded.

Temperature and pressure also influence adsorption efficiency. Lower temperatures generally enhance adsorption by reducing molecular kinetic energy, while higher pressures increase the concentration of molecules, driving more into the sieve’s pores. These factors are carefully controlled in industrial settings to optimize performance.

This precise adsorption principle makes molecular sieve indispensable in applications like natural gas purification, air drying, and solvent recovery, where selective separation is essential for product quality and process efficiency.