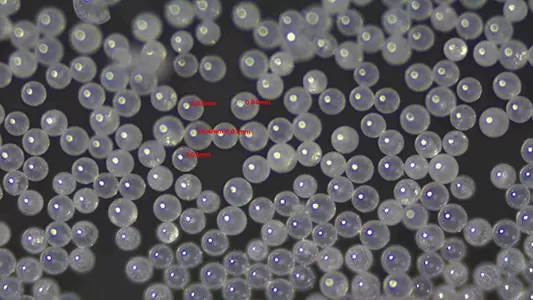

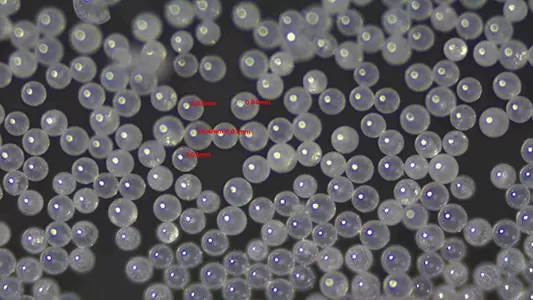

Industrial grinding ceramic balls include several types such as alumina, zirconia, silicon carbide, and silicon nitride ceramic balls, each with unique properties suitable for different grinding applications based on material hardness, abrasiveness, and process requirements. These balls play a crucial role in reducing particle size efficiently while minimizing contamination and wear, making them integral to industries like mining, ceramics, and pharmaceuticals.

Alumina ceramic balls are the most widely used in industrial grinding due to their cost-effectiveness and balanced performance. They are composed primarily of aluminum oxide (Al₂O₃), with purity levels ranging from 85% to 99%. Higher purity alumina balls (95% and above) offer superior hardness (Mohs 9) and wear resistance, making them ideal for grinding medium-hard materials like glass, ceramics, and minerals. Lower purity grades (85%) are more economical and suitable for less demanding applications such as grinding pigments or fertilizers, where extreme wear resistance is not critical.

Zirconia ceramic balls, made from zirconium dioxide (ZrO₂) stabilized with yttria or other oxides, stand out for their high toughness and impact resistance. Unlike brittle alumina, zirconia balls can withstand repeated impacts without cracking, making them suitable for grinding brittle or fragile materials like electronic ceramics and advanced composites. Their smooth surface reduces contamination, which is vital for pharmaceutical and food processing applications where product purity is paramount. Zirconia balls also perform well in wet grinding processes, resisting corrosion in aqueous or chemical environments.

Silicon carbide ceramic balls are prized for their extreme hardness (Mohs 9.5) and high thermal conductivity, making them the top choice for grinding very hard and abrasive materials. They excel in mining and mineral processing, where they efficiently grind ores, quartz, and refractory materials. Silicon carbide’s low density compared to other ceramics reduces energy consumption in high-speed mills, while its chemical inertness allows use in grinding acidic or alkaline substances without degradation. However, their brittleness limits their use in high-impact applications where toughness is required.

Silicon nitride ceramic balls offer a unique combination of high strength, thermal shock resistance, and low friction. Though less hard than silicon carbide, they maintain structural integrity at elevated temperatures (up to 1200°C), making them suitable for high-temperature grinding processes such as in cement production or metal powder manufacturing. Their low coefficient of friction reduces wear on mill liners, extending equipment lifespan, and their resistance to thermal cycling prevents cracking in processes with fluctuating temperatures.

Each type of industrial grinding ceramic ball is selected based on the specific demands of the application. Alumina balls balance cost and performance for general use, zirconia balls prioritize toughness and purity, silicon carbide balls handle the hardest materials, and silicon nitride balls excel in high-temperature environments. Understanding these differences ensures optimal grinding efficiency, reduced downtime, and improved product quality across industrial sectors.