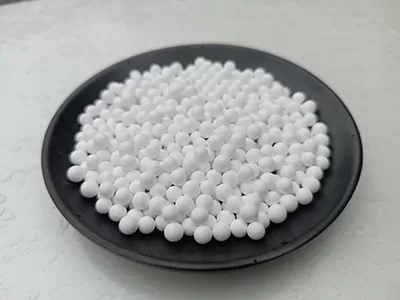

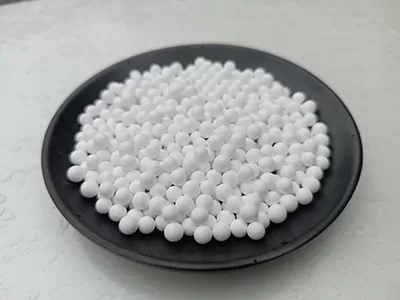

Grinding nano ceramic balls in ball mills exhibits unique characteristics, including high precision particle size control, minimal contamination, and enhanced surface smoothness, influenced by mill parameters, grinding media, and material properties. These characteristics are critical for producing nano ceramic balls with consistent performance suitable for advanced applications.

One key characteristic is ultra - fine particle size distribution. Ball mills used for grinding nano ceramic balls can achieve particle sizes as small as 10 to 100 nanometers, with narrow size ranges. This precision is achieved through controlled rotational speeds and the use of fine grinding media, such as zirconia or alumina beads, which apply gentle yet effective forces to reduce particle size without excessive agglomeration. The ability to maintain a tight particle size distribution ensures uniformity in the nano ceramic balls’ physical and chemical properties.

Minimal contamination is another notable feature. The grinding process uses ceramic grinding media that match the material of the nano ceramic balls, such as using zirconia beads to grind zirconia nano ceramic balls. This reduces the risk of cross - contamination from foreign materials, which is crucial for applications in electronics and medical devices where purity is paramount. Additionally, the inner linings of the ball mills are often made of the same ceramic material to further prevent contamination.

Enhanced surface smoothness is a result of the grinding process. Nano ceramic balls ground in ball mills exhibit exceptionally low surface roughness, often with Ra values below 0.1 μm. This smoothness is achieved through prolonged grinding cycles that gradually refine the surface, reducing irregularities. A smooth surface is essential for applications like precision bearings, where friction and wear must be minimized.

High grinding efficiency under optimized conditions is also a characteristic. By adjusting parameters such as mill rotational speed, grinding time, and the ratio of grinding media to nano ceramic balls, the grinding process can be optimized to achieve the desired particle size in a relatively short time. This efficiency is enhanced by the use of high - energy ball mills, which apply greater impact and shear forces to break down particles.

The grinding process also induces unique structural changes in the nano ceramic balls. It can lead to increased densification and reduced porosity, as the mechanical forces from the grinding media promote particle rearrangement and bonding. This results in nano ceramic balls with higher mechanical strength and improved durability, making them suitable for high - stress applications.

Moreover, the grinding process allows for good dispersibility of the nano ceramic balls. Proper grinding breaks down agglomerates, ensuring that the individual nano particles are well - dispersed. This is important for applications where the nano ceramic balls need to be uniformly distributed, such as in composite materials or coatings.

In summary, grinding nano ceramic balls in ball mills is characterized by precise particle size control, minimal contamination, smooth surfaces, high efficiency, structural improvements, and good dispersibility. These characteristics make ball mills a valuable tool for producing high - quality nano ceramic balls for a wide range of advanced industrial applications.