Ceramic ball wear resistance tests are conducted through specific methods to evaluate their durability under friction and abrasion, involving procedures like ball - on - disk testing, mill grinding trials, and weight loss measurement, with results guiding material selection and application suitability. These tests simulate real - world operating conditions to assess how well ceramic balls withstand wear over time, ensuring they meet performance requirements for specific uses.

Ball - on - disk testing is a common laboratory method. A ceramic ball is pressed against a rotating disk made of abrasive material, such as silicon carbide or steel, under controlled load and speed. The test measures the volume of material worn from the ball after a set duration, typically using a profilometer to quantify wear depth. This method is effective for comparing the wear resistance of different ceramic materials, like alumina and zirconia, under consistent conditions.

Mill grinding trials simulate industrial grinding environments. Ceramic balls are placed in a laboratory - scale ball mill along with abrasive media, such as quartz sand or ore particles, and rotated for a specified period. After the test, the balls are cleaned, dried, and weighed to calculate weight loss, a key indicator of wear. This trial reflects real - world performance in applications like mineral processing, where ceramic balls are used as grinding media, helping determine their service life in such settings.

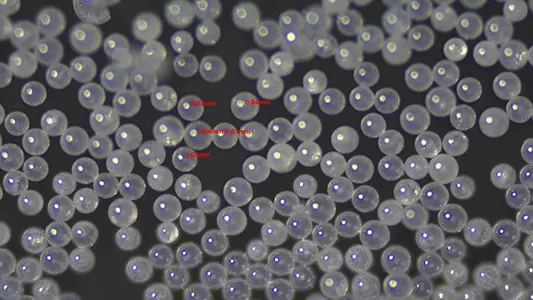

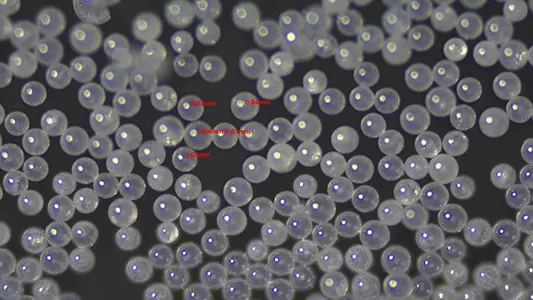

Abrasive slurry testing is used for evaluating wear resistance in wet conditions, relevant for applications like slurry pumps or chemical processing where ceramic balls come into contact with abrasive fluids. Ceramic balls are immersed in a slurry of abrasive particles and water, then subjected to rotational or vibrational motion. The wear is assessed by measuring changes in diameter or surface roughness, providing insights into performance in moist, abrasive environments.

For ceramic balls used as packing in industrial columns, specific wear tests are designed to mimic their interaction with flowing fluids and other packing materials. Balls are placed in a test column with circulating fluid containing abrasive particles, and after a set time, they are inspected for surface damage, cracks, or dimensional changes. This ensures the packing maintains its structural integrity and functionality in long - term service.

Standardized metrics are used to quantify wear results, including weight loss per unit time, volume loss, and surface roughness changes. These metrics allow for objective comparison between different ceramic types and manufacturing batches. High - precision instruments like balances with milligram accuracy and optical microscopes are used to ensure accurate measurements.

Environmental factors such as temperature and load are often varied in tests to assess their impact on wear resistance. For example, testing at elevated temperatures helps evaluate silicon nitride ceramic balls intended for high - temperature applications, ensuring their wear performance remains consistent under thermal stress.

In summary, ceramic ball wear resistance tests employ various methods tailored to specific applications, providing valuable data on durability and performance. These tests are crucial for selecting the right ceramic balls for industrial use, optimizing their lifespan, and ensuring reliable operation in diverse environments.