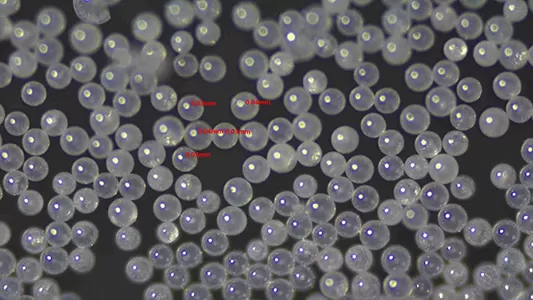

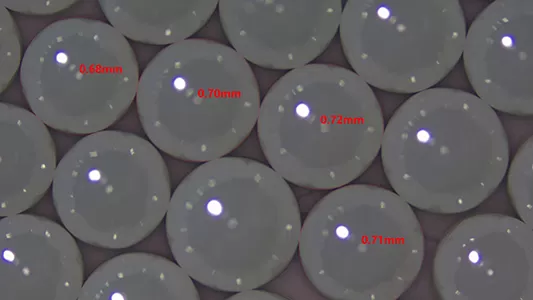

Zirconia ceramic balls are high - performance ceramic products made from zirconium dioxide (ZrO₂), celebrated for their outstanding toughness, wear resistance, and biocompatibility. Through specialized manufacturing processes, they achieve remarkable mechanical properties, making them suitable for diverse demanding scenarios. Compared to other ceramic balls, they offer a unique balance of strength and flexibility, which expands their application range significantly.

A key advantage of zirconia ceramic balls is their exceptional toughness, allowing them to withstand high impact and mechanical stress without shattering easily. They also exhibit excellent wear resistance, maintaining their integrity even in continuous friction environments. Additionally, their good thermal stability enables them to perform well in varying temperature conditions, from low to moderately high ranges.

In the medical field, zirconia ceramic balls are widely utilized due to their biocompatibility. They are often employed in dental implants, joint replacements, and medical devices where compatibility with human tissues is crucial. Their smooth surface and resistance to bodily fluids ensure long - term reliability and reduce the risk of adverse reactions.

The automotive industry also benefits from these ceramic balls. They are used in fuel pumps, valves, and bearing systems, where their wear resistance and ability to operate in harsh conditions contribute to improved performance and extended service life of vehicle components.

In the electronics sector, zirconia ceramic balls find application in precision instruments and sensors. Their dimensional stability and electrical insulation properties make them suitable for use in components that require accurate positioning and minimal interference with electrical signals.

Furthermore, in industrial processing, zirconia ceramic balls serve as effective packing in grinding mills and chemical reactors. As packing, they aid in efficient mixing and grinding processes while resisting corrosion from various chemicals, ensuring the purity of the end products and enhancing process efficiency.

In the jewelry industry, zirconia ceramic balls are sometimes used as substitutes for precious stones, thanks to their high hardness and ability to be polished to a brilliant shine, offering an affordable and durable alternative.

Overall, zirconia ceramic balls are versatile materials with a wide range of applications across multiple industries, driven by their unique combination of mechanical, chemical, and biological properties.