Selecting the right plastic packing is crucial for ensuring efficient and stable operation of industrial processes. This article will discuss the key factors and steps involved in selecting plastic packing.

First, understanding the specific process requirements is the foundation of selection. Different industrial processes, such as absorption, distillation, extraction, or heat transfer, have varying demands on plastic packing. For example, distillation processes often require packing with high mass transfer efficiency and a large specific surface area to facilitate the separation of components, while absorption processes may prioritize low pressure drop to reduce energy consumption. The operating parameters, including temperature, pressure, and the flow rates of gas and liquid, must also be considered. High-temperature environments, for instance, demand plastic packing made from heat-resistant materials like polytetrafluoroethylene (PTFE), while low-pressure systems may benefit from packing with a more open structure to minimize resistance.

The properties of the fluids involved are another critical factor. Corrosive fluids, such as strong acids or alkalis, require plastic packing with excellent chemical resistance. Polypropylene (PP) packing is suitable for many mild to moderate corrosive environments, while PTFE packing is ideal for highly aggressive chemical media. Viscous liquids or fluids containing solid particles call for packing with larger void spaces and a structure that resists fouling and clogging, such as grid packing. In contrast, for clean, low-viscosity fluids, structured packing with a high specific surface area can be a better choice to enhance contact efficiency.

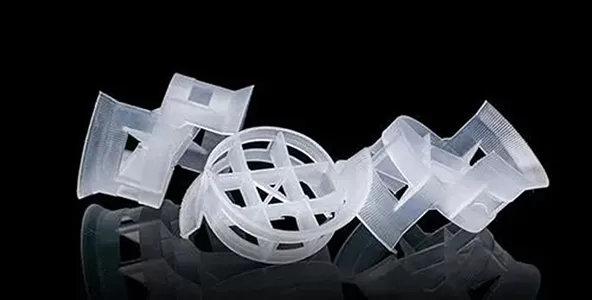

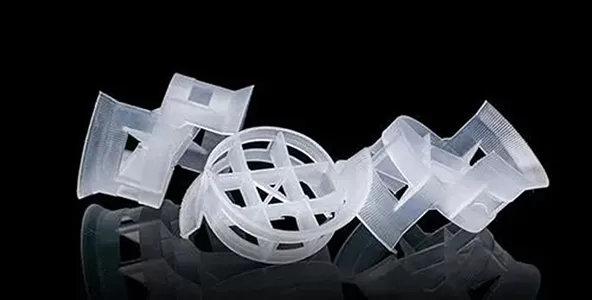

The structural characteristics of the plastic packing itself play a significant role in the selection process.

random packing, such as

pall rings or

saddle rings, is versatile and easy to install, making it suitable for small to medium-sized columns and processes with moderate efficiency requirements. Structured packing, with its ordered arrangement, offers higher mass transfer efficiency and lower pressure drop, making it appropriate for large-scale operations and processes that demand precise separation, such as pharmaceutical or fine chemical production. The size of the packing is also important: smaller packing provides a larger specific surface area but may increase pressure drop, while larger packing reduces pressure drop but offers less contact area. The choice of size depends on balancing efficiency and energy consumption.

Material selection is closely tied to the process conditions. As mentioned, PP is a cost-effective option for general applications with moderate temperatures and chemical exposure. Polyvinyl chloride (PVC) is resistant to many acids and alkalis but has lower heat resistance. PTFE, though more expensive, excels in extreme temperatures and highly corrosive environments. Polyethylene (PE) is suitable for low-temperature applications and has good impact resistance. Assessing the compatibility of the plastic material with the process fluids and operating temperature is essential to avoid degradation or failure of the packing.

Pressure drop and energy consumption are practical considerations. Packing that creates excessive pressure drop requires more energy to pump fluids through the system, increasing operational costs. For processes with high flow rates, packing with a more open structure, such as large-diameter Pall rings or grid packing, can help minimize pressure drop. Conversely, in processes where energy consumption is less critical but separation efficiency is paramount, structured packing with a higher pressure drop may be acceptable.

Installation and maintenance requirements should also be taken into account. Random packing is easier to install and replace, making it suitable for processes that require frequent maintenance or have limited access to the column. Structured packing, while more efficient, requires careful installation to ensure proper alignment and avoid channeling, which can reduce performance. Additionally, packing that is prone to fouling may require more frequent cleaning or replacement, affecting operational downtime and costs.

Finally, cost-effectiveness is a key factor in the selection process. While high-performance packing like PTFE structured packing may offer superior performance, it comes with a higher initial cost. For many standard industrial processes, PP random packing provides a good balance between performance and cost. Evaluating the total lifecycle cost, including installation, maintenance, and energy consumption, rather than just the upfront cost, ensures a more informed decision.

In summary, selecting plastic packing involves considering process requirements, fluid properties, structural characteristics, material compatibility, pressure drop, installation and maintenance needs, and cost-effectiveness. By carefully assessing these factors, one can choose the most suitable plastic packing to optimize industrial process efficiency and reliability.