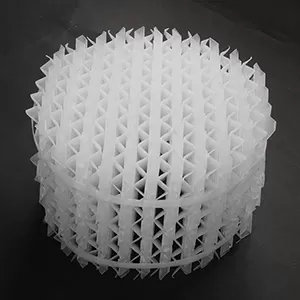

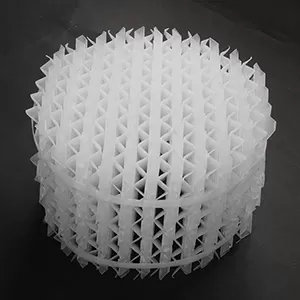

Resistance calculation of plastic

structured packing is crucial for designing and optimizing industrial separation equipment. This article will explore the factors influencing resistance and the methods for calculating it.

The specific surface area of plastic structured packing is a key factor affecting resistance. Packing with a larger specific surface area provides more contact points for fluids, increasing the frictional resistance between the fluid and the packing surface. For example, structured packing with a specific surface area of 250 m²/m³ will generally have higher resistance than that with 125 m²/m³ under the same flow conditions. This is because the increased surface area enhances the interaction between the gas and liquid phases, leading to greater pressure drop.

The geometry and arrangement of the packing also play a significant role. The corrugated angle, channel size, and alignment of the plastic structured packing determine the flow path of the fluids. Packing with smaller channel sizes or steeper corrugated angles can cause more turbulent flow, resulting in higher resistance. Conversely, larger channels and shallower angles allow for smoother fluid flow, reducing resistance. The uniformity of the packing arrangement is also important; irregularities or misalignments can create eddies and increase pressure drop.

Fluid properties, such as density and viscosity, influence resistance calculation. Gases with higher density or liquids with higher viscosity will experience greater frictional resistance when flowing through the packing. For instance, in absorption processes involving viscous liquids, the resistance of the plastic structured packing will be higher compared to processes with low - viscosity liquids. Changes in fluid properties due to temperature or pressure variations must also be considered, as they can alter the resistance characteristics.

Flow rates of gas and liquid are critical parameters in resistance calculation. Higher gas flow rates increase the kinetic energy of the gas, leading to greater impact and friction against the packing and liquid phase, thus increasing resistance. Similarly, excessive liquid flow rates can cause flooding, where the liquid fills the packing channels and significantly increases pressure drop. The ratio of gas to liquid flow rates also affects resistance; an imbalance can lead to uneven distribution and increased resistance in certain areas of the packing.

Several empirical and semi - empirical methods are used to calculate the resistance of plastic structured packing. The Eckert method, for example, correlates the pressure drop with the gas and liquid flow rates, packing specific surface area, and fluid properties. It uses dimensionless groups to account for the interactions between the phases. Another common approach is the Bravo - Rocha - Fair method, which considers the effect of packing geometry and fluid dynamics on pressure drop, providing more accurate results for certain types of structured packing.

Experimental data and manufacturer correlations are also valuable for resistance calculation. Manufacturers often provide pressure drop curves or correlations based on their specific packing designs, which are derived from extensive testing. These data can be used to validate theoretical calculations or as a primary reference in practical applications. It is important to select the appropriate correlation based on the type and specifications of the plastic structured packing being used.

In summary, resistance calculation of plastic structured packing involves considering factors such as specific surface area, geometry, fluid properties, and flow rates. Empirical methods, manufacturer data, and experimental validation are used to determine the pressure drop, which is essential for designing efficient and cost - effective separation equipment. Accurate resistance calculation ensures optimal operation and prevents issues such as excessive energy consumption or flooding.