Replacing

plastic packing in desulfurization towers is a key maintenance task to ensure efficient desulfurization. This article will outline a detailed plan for the replacement, including preparation, steps, and precautions.

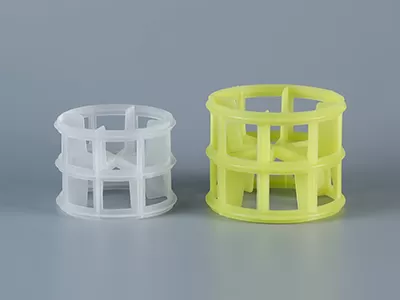

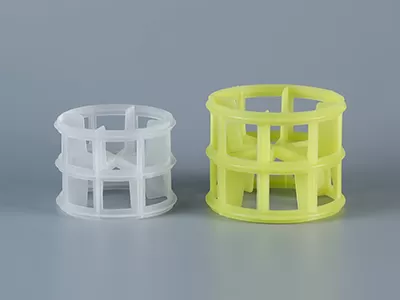

Pre - replacement preparation is essential. First, a thorough inspection of the desulfurization tower is required to assess the condition of the existing plastic packing, such as the degree of fouling, damage, or blockage. This helps determine the scope of replacement and the quantity of new packing needed. At the same time, the specifications of the new plastic packing must be confirmed to ensure they match the tower's design requirements, including size, material, and structural type, to guarantee optimal desulfurization efficiency.

Safety measures are a critical part of the preparation. Before starting the replacement work, the desulfurization tower must be shut down and isolated from the system to prevent the leakage of harmful gases or liquids. Ventilation should be carried out to reduce the concentration of toxic substances inside the tower. Workers must wear appropriate personal protective equipment, such as gas masks, gloves, and safety harnesses, to ensure their safety during the operation.

The replacement steps involve several stages. The first step is to remove the old plastic packing. This is usually done manually, with workers entering the tower (or using tools from the top) to take out the damaged or worn packing. During removal, care should be taken to avoid causing further damage to the tower's internal components, such as the distribution plates or support grids. The removed packing should be properly disposed of according to environmental protection regulations to prevent pollution.

After removing the old packing, the tower's interior needs to be cleaned. This includes washing the tower walls, distribution plates, and support structures to remove any accumulated dust, scale, or residual contaminants. A clean surface ensures good contact between the new packing and the tower components, which is beneficial for the uniform distribution of the desulfurizing liquid and gas.

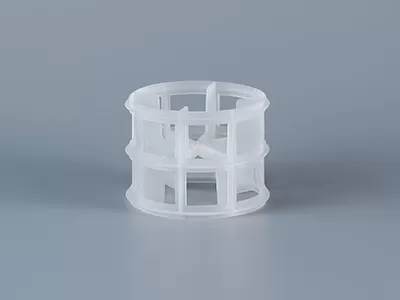

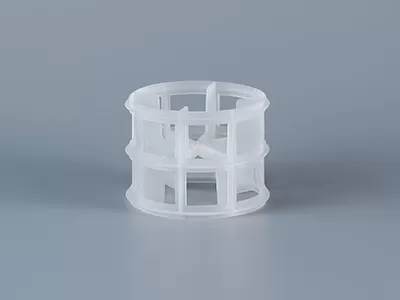

Installing the new plastic packing is the next step. The packing should be loaded into the tower in an orderly manner, ensuring even distribution and avoiding uneven stacking, which could lead to uneven gas - liquid flow. For

structured packing, attention must be paid to the correct orientation during installation to maximize the contact area between the gas and liquid. After installation, a check should be performed to ensure there are no gaps or overlaps that could affect the desulfurization process.

Post - replacement testing is necessary to verify the effectiveness of the replacement. The desulfurization tower is restarted, and parameters such as gas flow rate, liquid spray density, and desulfurization efficiency are monitored. If any abnormalities are found, adjustments should be made promptly, such as re - arranging the packing or checking for leaks in the system.

Precautions during the replacement process should not be ignored. The installation of the new packing must be carried out in accordance with the manufacturer's instructions to avoid improper installation that may reduce its performance. During the work, the tower's internal pressure and temperature should be monitored to prevent unexpected changes. Additionally, the disposal of waste packing must comply with environmental standards to avoid causing environmental pollution.

In conclusion, a well - planned replacement of plastic packing in desulfurization towers, including careful preparation, strict adherence to safety measures, proper execution of replacement steps, and attention to precautions, is crucial for maintaining the tower's desulfurization efficiency and ensuring the safety and environmental friendliness of the operation.