The heat resistance of plastic packing is a key factor affecting its application in high - temperature environments. This article will discuss the heat resistance of plastic packing, the factors influencing it, and the performance of different types of plastic packing under high temperatures.

The material composition of plastic packing is the primary determinant of its heat resistance. Packing made from high - temperature resistant polymers, such as polytetrafluoroethylene (PTFE) or polyimide, generally exhibits excellent heat resistance. These materials have strong chemical bonds and stable molecular structures, enabling them to maintain their properties even at relatively high temperatures. In contrast, packing made from polyethylene or polypropylene, which are low - melting point polymers, has poor heat resistance and may soften or decompose when exposed to high temperatures.

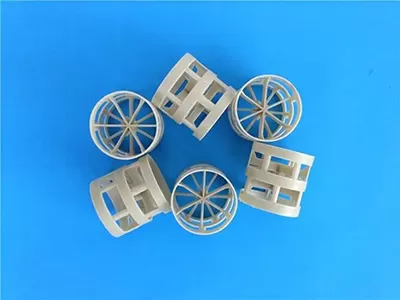

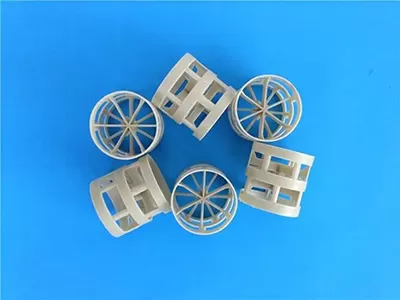

The structure of the packing also plays a role. Packing with a dense and uniform structure tends to have better heat resistance than those with porous or irregular structures. The dense structure reduces the penetration of heat and prevents rapid thermal degradation. Additionally, some packing is modified through cross - linking or other processes to enhance its structural stability, thereby improving heat resistance.

Environmental factors can affect the heat resistance of plastic packing. For example, in the presence of oxygen, high temperatures may accelerate the oxidation of the packing, reducing its heat resistance. Chemical substances in the environment, such as acids, alkalis, or solvents, can also interact with the packing at high temperatures, leading to degradation and loss of performance.

Different application scenarios have varying requirements for the heat resistance of plastic packing. In industries such as automotive manufacturing, where parts may be exposed to high temperatures during operation, plastic packing with high heat resistance is necessary. In contrast, in daily consumer goods that are not used in high - temperature environments, the heat resistance requirement for packing is relatively low.

Testing the heat resistance of plastic packing usually involves exposing it to different high - temperature environments for a certain period and then evaluating changes in its physical and mechanical properties, such as hardness, tensile strength, and impact resistance. This helps determine the maximum temperature at which the packing can maintain its performance.

In conclusion, the heat resistance of plastic packing varies depending on material composition, structure, and environmental factors. Understanding these factors is crucial for selecting the appropriate plastic packing for different high - temperature applications to ensure the reliability and performance of the products.