The plastic rectangular saddle ring is a circular chemical packing material made of polypropylene (PP). Its structure is achieved by changing the arc-shaped surface of the traditional arc saddle ring into a rectangular one, which avoids the problem of packing layering and improves the uniformity of the bed layer's porosity. The plastic rectangular saddle ring is designed with a difference in the inner and outer curvature radii, which enhances the liquid distribution performance. The gas-liquid mass transfer efficiency is significantly improved compared to traditional packing materials.

The smooth arc-shaped side of the plastic polypropylene rectangular saddle ring increases the contact gaps between the packing materials within the packing bed, making it more conducive to the flow and diffusion of gas and liquid in the packing layer. The surface has certain gaps, allowing gas to flow through here, and the internal pressure will thus decrease, further enhancing its performance.

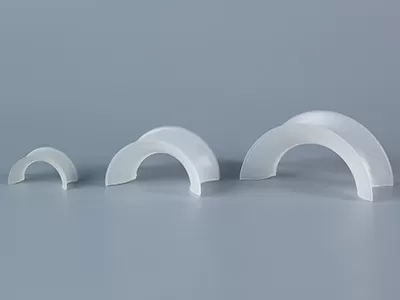

Specifications:

| Name | Dimension | Diameter×Height×Thickness | Surface area | Void space | Bulk density | No.elements | Packing factor |

| mm | mm | m2/m3 | % | kg/m3 | per/m3 | m-1 | |

| Plastic Saddle Ring | Φ25 | 25×13×1.2 | 288 | 85 | 102 | 97680 | 467 |

| Φ38 | 38×19×1.2 | 265 | 95 | 91 | 25200 | 309 | |

| Φ50 | 50×25×1.5 | 250 | 96 | 75 | 9400 | 282 | |

| Φ76 | 76×38×3.0 | 200 | 97 | 59 | 3700 | 220 |

The plastic rectangular saddle ring packing material has good corrosion resistance and heat resistance, and is widely used in extraction towers. Its shape is between circular and saddle-shaped, having the advantages of both, which is conducive to liquid distribution, increasing gas channels, and having lower resistance, higher flux, better packing strength and stiffness compared to the Bauer ring, and is currently widely used as a bulk packing material.

The rectangular saddle ring is processed by a continuous extrusion process. Compared with the same material Raschig ring packing material, the rectangular saddle ring has the advantages of high flux, low pressure, and high efficiency. Its bed layer has a large porosity. The shape of the rectangular saddle ring is between circular and saddle-shaped, combining the advantages of both, which is conducive to liquid distribution and increasing gas channels.

.png)

.png)

.png)

.jpg)

.jpg)