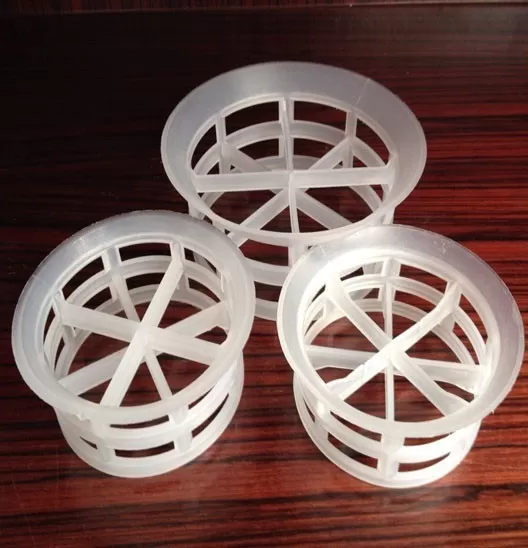

Firstly, the structure design of the plastic cascade ring is unique, presenting a cascadeped shape, similar to the shape of a staircase. This design is beneficial for increasing the surface area of the packing material, improving the efficiency of gas-liquid contact, and thereby promoting the progress of the mass transfer process. The side ends of the plastic cascade ring are provided with flanges, which not only increase the mechanical strength of the packing ring but also increase the probability of orientation when the packing is placed due to the disruption of the symmetry of the packing structure. This structural design enables the plastic cascade ring to have better mass transfer efficiency and uniform liquid distribution in the packing tower.

Specification

| Name | Normal | Diameter×Height×Thickness | Surface area | Void space | Bulk density | No.elements | Packing factor |

| mm | mm | m2/m3 | % | kg/m3 | per/m3 | m-1 | |

| Plastic Cascade Ring | Φ25 | 25×13×1.2 | 228 | 90 | 98 | 81500 | 313 |

| Φ38 | 38×19×1.4 | 133 | 93 | 58 | 27200 | 176 | |

| Φ50 | 50×25×1.5 | 114 | 94 | 55 | 10740 | 143 | |

| Φ76 | 76×37×3.0 | 90 | 93 | 698 | 3420 | 112 |

Secondly, the plastic cascade ring is mainly made of plastic materials such as polypropylene (PP), reinforced polypropylene (RPP), polyvinyl chloride (PVC), chlorinated polyvinyl chloride (CPVC), and polyvinylidene fluoride (PVDF). Different materials of the plastic cascade ring are suitable for different working conditions, such as temperature, pressure, and medium. Users can choose the appropriate material of the plastic cascade ring according to specific needs to ensure that the packing has good stability and corrosion resistance during operation.

In addition, plastic cascade rings have wide applications in the industrial field. They are often used in packing towers in fields such as chemical engineering, petroleum, and environmental protection, for processes such as gas absorption, washing, and cooling. Plastic cascade rings have the advantages of corrosion resistance, anti-pollution, small volume, and high flow rate, which can improve the operating efficiency and mass transfer efficiency of the process equipment.

.png)

.png)

.jpg)

.jpg)

.png)